Services

Study and design

Starting from an architectural or design project, our technical department develops the solution best suited to the client’s needs, from the on-site survey to the drafting of the executive drawing, always keeping an eye on design trends and offering innovative and customized solutions.

Turnkey

State-of-the-art machinery, excellent raw materials, expert labor from master craftsmen, and a team ready to respond to every need allow Mondial Marmi to offer its customers a turnkey package.

Nautical refitting

Thanks to the great experience gained over the years in the nautical sector, Mondial Marmi offers, in addition to numerous design services, the refit of spaces that were previously fitted out, but of which the client needs to renew the appearance or upgrade their boat both aesthetically and functionally-technologically.

Technologies

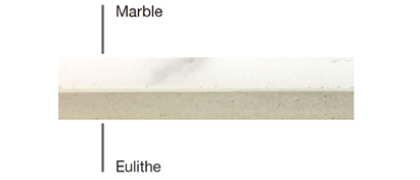

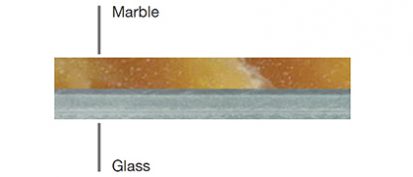

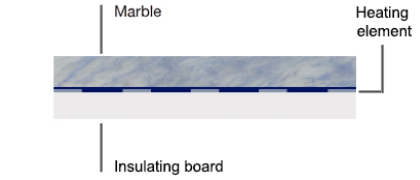

Learn more about the technologies we use to lighten, strengthen, backlight, and heat our materials, making them applicable to any context.