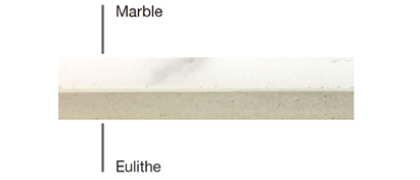

Eulithe

In the landscape of innovative materials for the nautical, architectural, and furniture industries, Eulithe stands out as a polyurethane foam with exceptional properties.

Innovation in foam materials for premium applications

This material is made of a rigid thermosetting polymer, formulated with particularly sophisticated chemical compositions that give the final product technical and functional properties superior to traditional materials.

Technical characteristics of the Eulithe

Eulithe is valued for its light weight, strength and versatility. Its expanded structure allows it to maintain low weight without compromising strength, making it ideal for applications where weight is critical. Due to its advanced formulation, Eulithe offers superior performance in terms of mechanical strength, thermal insulation and chemical resistance.

One of the most attractive features of Eulithe is its ability to be used in large formats while maintaining its structural properties. This is particularly advantageous for the marine and architectural industries, where materials must often cover large areas without risk of warping or sagging.

Applications of Eulithe

Nautical: In the nautical sector, Eulithe finds use in a wide range of applications due to its light weight and water resistance. It is used for interior furnishings, walls, flooring, false ceilings and cladding.

Architecture: In architecture, it is used for curtain and ventilated facades as well as wall cladding. The possibility of using the material in large formats allows for homogeneous surfaces without visible joints, improving the aesthetics and performance of buildings.

Furniture: In the field of furniture, Eulithe is used to make desks, tables, vanity tops and kitchens. Its versatility makes it possible to create furniture with innovative design and high functional performance. In addition, the lab surface finish can be customized to meet the specific aesthetic requirements of each project.

Innovation and Sustainability

Eulithe represents not only high performance, but also sustainability. Its production uses advanced chemical processes that minimize environmental impact, while the material’s light weight helps reduce energy consumption during both transportation and installation.

Other technologies:

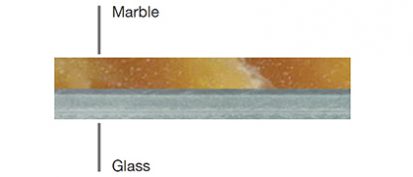

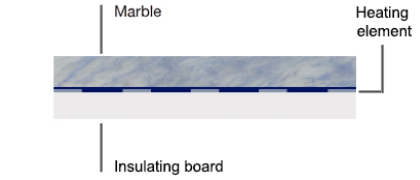

Technologies

Learn more about the technologies we use to lighten, reinforce, backlight, and heat our materials, making them suitable for any context.

Honeycomb

Through this support, it is possible to reduce the weight of the material, making it suitable for any context.